What Are 3D Printed Diecast Parts

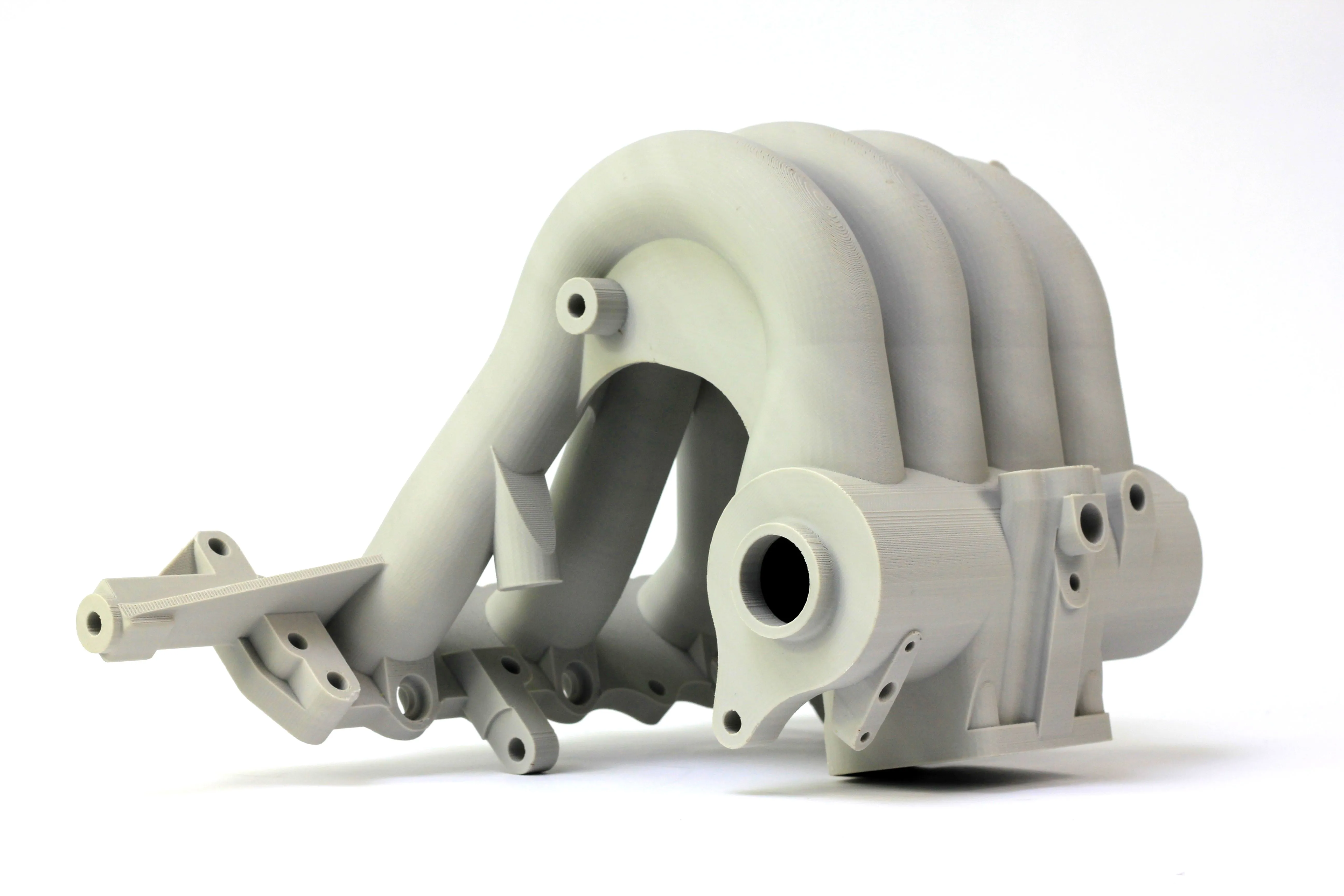

3D printed diecast parts represent a fusion of two powerful manufacturing technologies additive manufacturing and die casting. Traditional die casting involves injecting molten metal into a mold under high pressure to create parts. 3D printing, on the other hand, builds parts layer by layer from a digital design. When combined, 3D printing can create the molds (dies) used in the die casting process, or even directly print certain components, offering remarkable flexibility and efficiency. This approach allows for the creation of complex geometries, rapid prototyping, and on-demand manufacturing, which is increasingly important in various industries. Furthermore, this combination makes it possible to produce highly customized parts, which are not possible with traditional processes. The technology has seen remarkable progress in recent years.

Faster Prototyping and Design Iterations

One of the most significant advantages of using 3D printing in conjunction with die casting is the ability to rapidly prototype and iterate designs. Instead of waiting weeks for traditional tooling, 3D printing allows manufacturers to create molds quickly. This speed is invaluable during the design phase, enabling engineers to test multiple versions, identify flaws, and refine the design before investing in mass production tooling. The iterations can be performed in a matter of days or even hours, significantly shortening the product development cycle. This leads to faster time-to-market and reduces the risk of costly errors. This method also helps in refining the die casting parameters, thus improving the quality of the die cast components.

Rapid Production

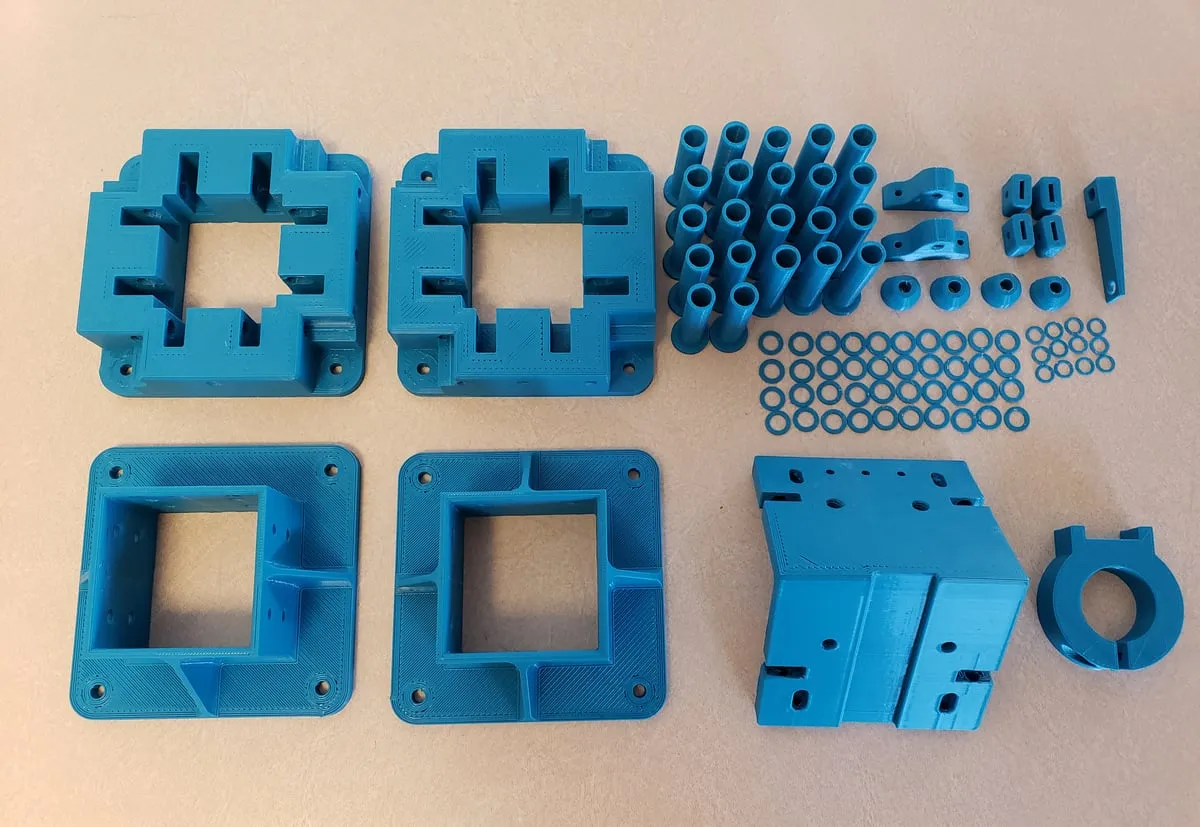

3D printing allows for faster production of the molds, also facilitates rapid production runs, especially for low-volume orders. With the ability to quickly produce molds, manufacturers can meet demands with agility, unlike traditional die casting, which requires extensive setup times for tooling. This is especially beneficial for custom components and specialized equipment, and reduces the necessity for lengthy setup times and large-scale production runs. For complex parts, 3D printing can produce molds with intricate details that may be difficult to achieve with conventional methods, ensuring high accuracy and quality. The speed and flexibility contribute to the growing adoption of 3D printed diecast parts.

Cost-Effectiveness for Low Volumes

3D printed diecast parts are very cost-effective, particularly for low-volume production runs. The primary cost associated with die casting is the manufacturing of the mold. Traditional methods often require expensive tooling, while 3D printing offers a more economical solution. By using 3D printing to create the molds, manufacturers can reduce these upfront costs. This makes 3D printing an ideal choice for small production runs, custom parts, and prototypes. As a result, businesses can test product viability without the need for significant investments. Furthermore, the elimination of costly tooling significantly benefits businesses, especially startups and small to medium enterprises (SMEs).

Improved Design Freedom and Complexity

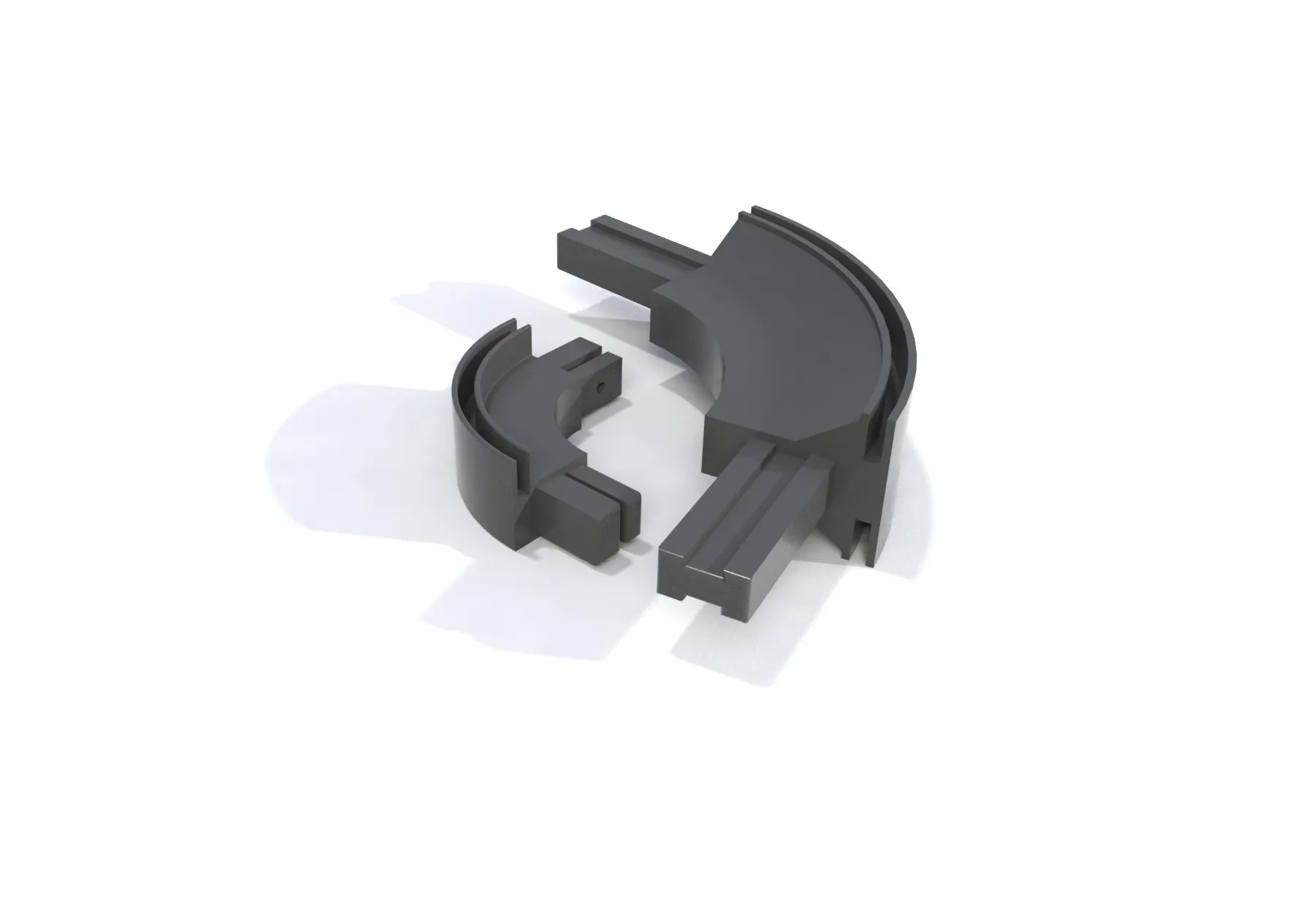

3D printing provides the ability to create highly complex geometries and intricate designs that are impossible or very difficult to achieve with traditional die casting methods. The ability to produce complex parts allows engineers to design parts with optimal performance and functionality. This design freedom enhances the overall part efficiency and performance, which would otherwise be severely limited. Furthermore, it enables designs with internal channels, undercuts, and other features that are not possible with conventional techniques. This enhances both the functional and aesthetic properties of the end product, providing significant competitive advantages.

Enhanced Material Properties

The materials utilized in 3D printed diecast parts can be meticulously chosen to attain specific mechanical and physical characteristics. This level of control over material selection is not always available in traditional die casting. 3D printing allows for the selection of materials that are appropriate for a variety of applications, with the option to adapt to extreme temperatures, chemical exposure, and demanding environments. This adaptability is particularly beneficial in industries requiring high-performance components, such as aerospace, automotive, and medical devices. The ability to select materials with high strength-to-weight ratios, superior corrosion resistance, and optimal thermal stability enhances the longevity and dependability of the final products.

Reduced Waste

3D printing generally produces less waste compared to traditional manufacturing processes. The additive nature of 3D printing means material is only used where it is needed, reducing excess material. This minimal waste translates to a lower environmental footprint. It allows for the efficient use of materials, which in turn benefits the environment. For manufacturers, this can translate into lower material costs and decreased waste disposal expenses. Furthermore, the use of recycled materials in 3D printing is also contributing to the industry’s sustainability efforts.

On-Demand Manufacturing and Customization

3D printing facilitates on-demand manufacturing and mass customization. This flexibility allows manufacturers to respond quickly to changes in demand and market trends. This approach makes it possible to manufacture components only when they are needed, reducing the need for large inventories. In addition, it allows for the production of customized parts tailored to unique specifications and requirements. This capacity is especially advantageous for specialized equipment, prototypes, and products requiring unique configurations. On-demand manufacturing and customization improve efficiency, reduce waste, and enable businesses to satisfy customer demands more effectively.

7 Benefits of 3D Printed Diecast Parts

Benefit 1 Faster Production of Prototypes

As discussed, 3D printing speeds up the prototyping process, reducing lead times and allowing for more design iterations. The ability to quickly produce prototypes helps engineers test designs and make adjustments, and ultimately reduces the cost and time associated with product development.

Benefit 2 Optimized Design and Performance

The design freedom offered by 3D printing enables manufacturers to optimize part designs for improved performance. Complex geometries and intricate features improve functionality. The use of 3D printing opens doors for new advancements in product design.

Benefit 3 Reduced Material Waste

3D printing uses materials more efficiently than traditional manufacturing, resulting in less waste. This advantage contributes to sustainability efforts and reduces manufacturing costs.

Benefit 4 Enhanced Design Flexibility

The ability to produce complex geometries and custom designs enables innovation in product development. This flexibility facilitates the creation of parts with features that improve functionality and aesthetics.

Benefit 5 Lower Costs for Low-Volume Production

3D printing eliminates the need for expensive tooling, making it more cost-effective for small production runs. This cost advantage is especially valuable for prototyping, custom parts, and niche products.

Benefit 6 Improved Part Strength and Durability

Precise material selection and customized designs can improve the strength and durability of 3D printed diecast parts. This ensures that parts can withstand the demands of their applications.

Benefit 7 Faster Time to Market

Rapid prototyping, faster production runs, and efficient design iteration accelerate product development. The ability to reduce lead times is advantageous in competitive markets, where speed is critical.

Conclusion

3D printed diecast parts offer numerous advantages, making them a valuable tool in the manufacturing industry. From faster prototyping and increased design freedom to cost savings and reduced waste, the benefits are clear. As technology continues to evolve, the applications and capabilities of 3D printed diecast parts will only expand, offering new opportunities for innovation and efficiency.