What Are Diecast Toys?

Diecast toys, cherished by collectors and enthusiasts alike, are miniature replicas primarily made from metal, typically zinc alloy, and other materials. These toys are known for their durability, intricate detailing, and realistic appearance, often mirroring real-life vehicles such as cars, trucks, airplanes, and even military vehicles. The term “diecast” refers to the manufacturing process, where molten metal is injected into a mold under high pressure. This process allows for the creation of complex shapes and fine details that are characteristic of diecast models. Diecast toys are not just playthings; they represent a fascinating blend of artistry, engineering, and a passion for collecting.

The History of Diecast Toys

The history of diecast toys is a captivating journey that spans over a century, evolving from simple metal toys to highly detailed collectibles. The earliest diecast toys emerged in the early 20th century, initially crafted from lead and then zinc alloys due to their lower melting points and ease of molding. Companies like Meccano, with their Dinky Toys, and Lesney Products, the creators of Matchbox, revolutionized the industry with their innovative designs and mass-production techniques. The post-World War II era saw a boom in diecast toy popularity, with more realistic models and intricate details becoming the norm. Today, the diecast toy industry continues to thrive, driven by nostalgia, collecting, and the enduring appeal of these miniature masterpieces. These toys reflect not just a childhood memory but also technical evolution.

Materials You Need to Make Diecast Toys

Creating your own diecast toys requires a careful selection of materials. The primary material is the metal alloy used for the main body and components of the toy. Other important materials include plastics for details, wheels, and interior components and paints and coatings. The quality of materials directly impacts the final product’s durability and aesthetic appeal. Careful selection is key to the success of your project.

Zinc Alloy

Zinc alloy is the backbone of most diecast toys. This alloy, a blend of zinc with other metals like aluminum, magnesium, and copper, provides a good balance of strength, low melting point, and castability. Zinc alloy’s ability to capture intricate details is one of the major reasons it is widely used in diecast manufacturing. The alloy composition can vary, impacting the final toy’s strength and resistance to corrosion. The selection of the right zinc alloy is critical in ensuring the quality and durability of the diecast toy. Zinc alloy is usually chosen for its ability to allow detailed designs.

Plastics

Plastics play a vital role in adding detail and functionality to diecast toys. Various types of plastic are used for creating components such as the interior, wheels, windows, and other accessories. The choice of plastic depends on its properties. For example, a rigid plastic might be used for the chassis, while a flexible plastic might be selected for the tires. The quality and type of plastic significantly impact the toy’s aesthetics, durability, and overall playability. Plastic parts enhance the realism of the toy and make it look more attractive.

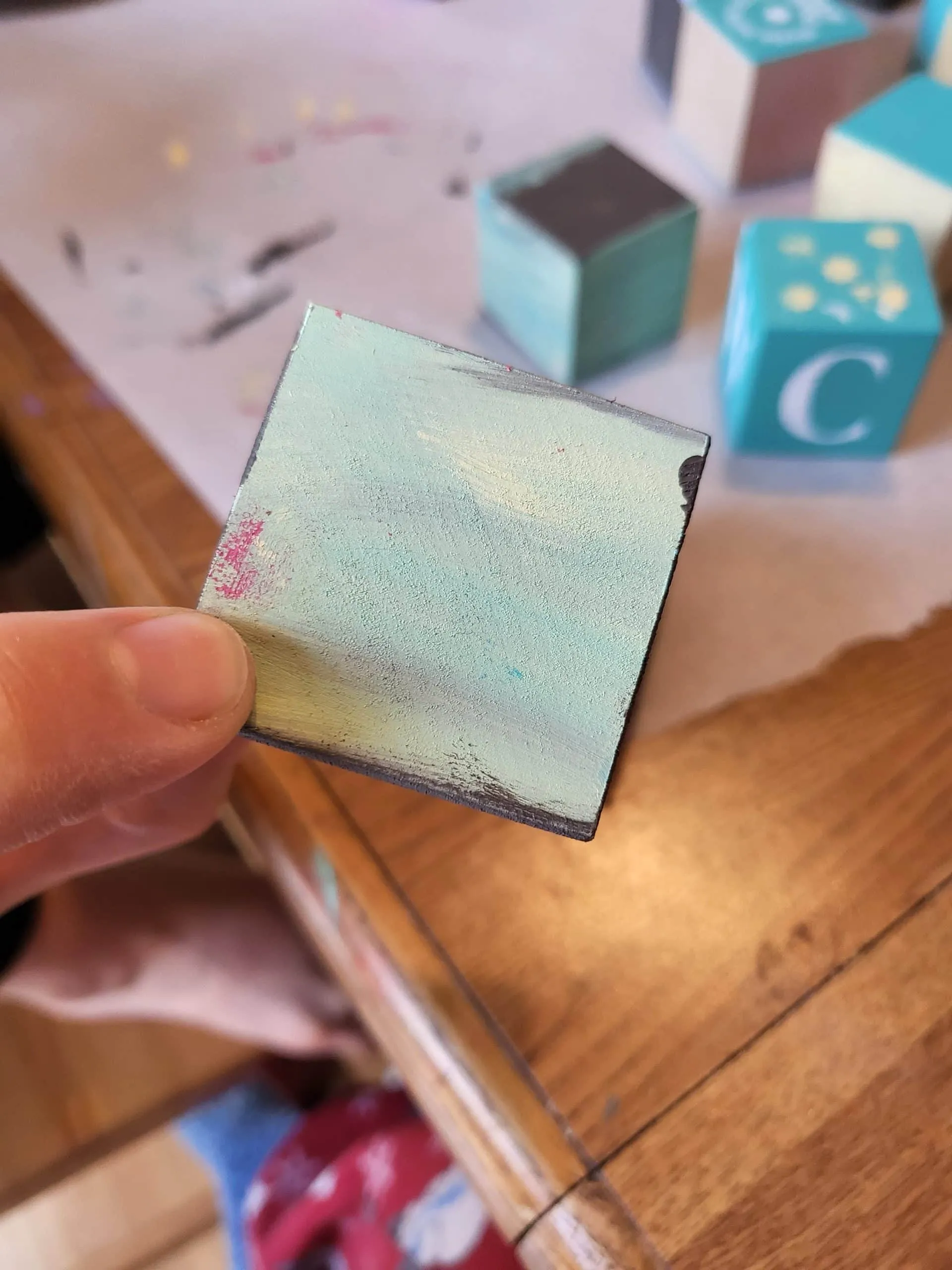

Paints and Coatings

Paints and coatings are essential for giving diecast toys their final look and protecting them from wear and tear. High-quality paints provide vibrant colors and a smooth finish, while clear coatings add shine and protect the paint from scratches and fading. The choice of paint and coating materials is critical. The paints must adhere well to the metal and plastic surfaces and must be resistant to chipping, fading, and chemical exposure. The right coatings give the toys a professional finish and extend their lifespan, making them more appealing to collectors and enthusiasts.

Tools for Diecast Toy Creation

Creating diecast toys involves specialized tools and equipment, with each serving a specific purpose in the manufacturing process. The tools used will depend on the level of detail and the production volume. From mold creation to finishing touches, each tool plays a crucial role in transforming raw materials into finely crafted models.

Melting and Molding the Metal

The process begins with melting the zinc alloy, usually in a furnace designed for this purpose. The alloy is heated to its melting point, ensuring a consistent temperature and quality. The molten metal is then injected into a mold under high pressure, which fills the mold’s cavities, capturing every detail of the toy’s design. Precision in this step is crucial, as it affects the final product’s accuracy and surface finish. Proper melting and molding are the foundation of a successful diecast toy, forming the toy’s structure and details.

Creating the Mold

The mold is a critical component in diecast toy production. It’s usually crafted from hardened steel and designed to withstand the high pressure and temperatures involved in the casting process. The mold’s design is meticulously created to replicate the toy’s features, from its overall shape to intricate details. The mold consists of two or more parts that fit together to form the cavity where the molten metal is injected. Precision in mold creation is vital, as the mold directly impacts the final product’s quality, details, and dimensional accuracy. The mold is a significant factor in the cost of diecast toy production.

Pouring the Molten Metal

Once the mold is prepared, the molten metal is injected into the mold under high pressure. This ensures that the metal fills all the cavities and captures the design details accurately. The pressure used in this step is crucial for producing a dense, high-quality casting. During the injection process, the metal is kept at a consistent temperature, and the injection rate is carefully controlled. Skilled operators manage this process, monitoring and adjusting variables to ensure the final product meets quality standards. The pouring stage is a precise and time-sensitive operation that requires expertise.

Cooling and Solidification

After the molten metal fills the mold, the next step is cooling and solidification. The mold is designed to allow for controlled cooling. This is essential for preventing defects such as shrinkage and porosity, which can affect the final product’s structural integrity. The cooling process usually takes place in the mold itself or is followed by a secondary cooling stage. The cooling time and temperature are carefully managed to ensure that the metal solidifies uniformly and that the toy retains its shape and dimensions. This is the final step that transforms the liquid metal into a solid part.

Preparing the Diecast Components

After the casting is complete, the diecast components undergo a series of preparation steps. This includes removing any excess material, such as flash, that may have formed during the molding process. The components also undergo surface treatments like sandblasting, polishing, or grinding, depending on the desired finish. These steps prepare the surfaces for painting and detailing. Each component must be thoroughly cleaned to ensure that the paint adheres properly. Preparation is essential for creating a smooth, high-quality surface for the final product.

Assembling the Diecast Toy

Assembling a diecast toy is a meticulous process that brings together the individual components to create a finished product. This involves carefully attaching the various parts using techniques such as screws, rivets, or adhesives. Skilled workers assemble the toys, ensuring that each part fits correctly and that the toy functions as intended. Wheels, axles, windows, and interior components are all carefully added during this step. Assembly requires precision, attention to detail, and a thorough understanding of the toy’s design. It’s the stage where all the different elements of the toy come together to create the final look.

Painting and Detailing

Painting and detailing are crucial in bringing diecast toys to life. The painting process typically involves applying several layers of paint to create the desired colors and finishes. This can include base coats, topcoats, and clear coats for protection and shine. The detailing process adds intricate features like decals, logos, and other design elements that enhance the toy’s realism and collectibility. The paint and detailing are applied using automated processes and skilled hand-painting techniques, depending on the complexity. Careful attention to detail in this stage transforms a metal casting into an attractive model.

Quality Control and Finishing Touches

Quality control is a critical step in diecast toy production, ensuring that each toy meets the required standards of quality, detail, and functionality. Quality control checks are carried out throughout the manufacturing process, from the raw materials to the final assembly. Inspectors examine the toys for defects, such as imperfections in the paint or misaligned components. Any defects found are corrected or rejected to ensure the final product meets the high standards. Finishing touches, such as the addition of accessories or packaging, are added at this stage to prepare the toys for sale.

Common Mistakes and How to Avoid Them

Making diecast toys can be a complex process, and many mistakes can be made along the way. The most common mistakes include poor mold design, insufficient metal temperature, and improper surface preparation. To avoid these, it is vital to create molds with precision and attention to detail and to use correct metal temperatures. Thorough surface preparation ensures that paint and coatings adhere properly, preventing chipping and other defects. Regular inspection throughout the manufacturing process can identify issues early and minimize waste, leading to higher quality results.

Safety Precautions When Working with Molten Metal

Working with molten metal involves several safety precautions. The most important is wearing proper personal protective equipment (PPE), including heat-resistant gloves, safety glasses, and a face shield. Make sure your work area is well-ventilated. Any moisture near molten metal can cause an explosion. Regularly inspect equipment for wear and tear, and maintain your equipment. Following these safety precautions will help to minimize the risk of accidents and create a safe working environment.

Tips for Improving the Quality of Your Diecast Toys

To improve the quality of diecast toys, you must focus on several key aspects. Start by investing in high-quality materials, especially the metal alloys, paints, and coatings. Make sure you use precise molds to accurately capture the details of the design. Rigorous quality control checks throughout the process are essential. Continuous improvement is key. Learn from each project. By implementing these strategies, you can ensure that each toy is of the highest quality.

Making diecast toys is a rewarding process that combines technical skill and creative expression. Whether you’re a hobbyist or a professional, by following these steps and paying attention to details, you can make high-quality diecast toys.